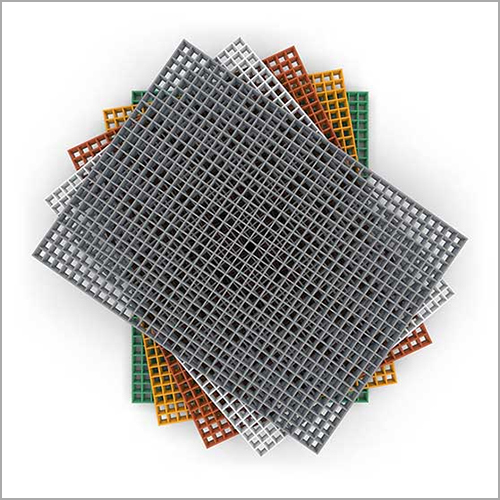

Industrial FRP Grating

Price 1200 INR/ Square Meter

Industrial FRP Grating Specification

- Diameter

- Mesh size: 25 mm x 25 mm, 38 mm x 38 mm, others as per requirement

- Shape

- Rectangular, Square, Mesh

- Product Type

- FRP

- General Use

- Industrial Flooring, Walkways, Drain Covers, Stair Treads, Platforms

- Material

- Fiberglass Reinforced Plastic (FRP)

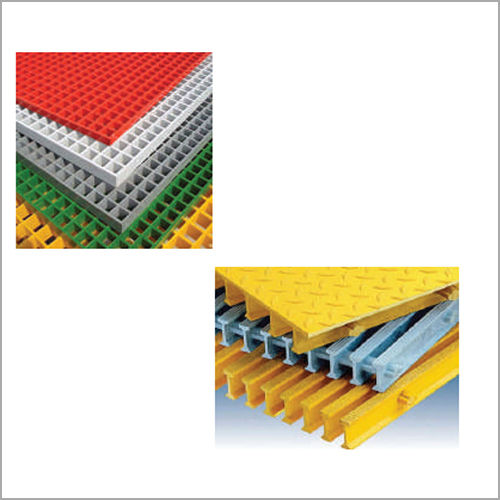

- Type

- Molded/ Pultruded Grating

- Capacity

- High Load Bearing Capacity

- Weight (kg)

- Varies as per size and thickness, typically 12-60 kg/m2

- Computerized

- No

- Automatic

- No

- Touch Screen

- No

- Control System

- Manual

- Surface Treatment

- Anti-slip Coated, Smooth/Concave Finish

- QC System

- ISO 9001:2015 Certified

- Tolerance

- 2 mm

- Drawing

- Available on Request

- Dimension (L*W*H)

- 1220 mm x 3660 mm, 1000 mm x 4000 mm or customized

- Feature

- Corrosion Resistant, Anti-slip, Lightweight, Non-conductive, UV Resistant, Chemical Resistant

- Color

- Green, Yellow, Grey, Customized

- Water Absorption

- < 1% by weight

- Fire Retardance

- Meets ASTM E84 Class 1

- Impact Resistance

- High

- Installation

- Easy to Install, Can be Cut to Size on Site

- Applicable Standards

- ASTM, BS, EN, DIN, IS standards depending on region

- Service Life

- 15+ years under standard industrial environments

- Load Bar Thickness

- 3-7 mm (standard sizes available)

- Operating Temperature

- -40°C to +120°C

- UV Stability

- Excellent, suitable for outdoor use

- Open Area

- Approximately 60-70% depending on mesh design

About Industrial FRP Grating

Your search for top-grade Industrial FRP Grating ends here. We are a trusted entity in this space which is involved in the process of manufacturing and supplying premium quality range of item to our consumers. It helps in lessening the expense of upkeep. This item has different applications where it is utilized, for example, walkways, overhead stages and some more. Offered Industrial FRP Grating is strictly inspected by our professionals on the various quality parameters before final dispatch.

Superior Performance in Harsh Environments

Industrial FRP Grating stands out for its exceptional resistance to corrosion, chemicals, UV radiation, and heavy impacts, making it an optimal choice where traditional materials fail. Its anti-slip, lightweight, and non-conductive properties add extra safety and utility in demanding industrial settings. With fire retardance conforming to ASTM E84 Class 1 and less than 1% water absorption, this grating provides reliability and safety in diverse conditions.

Customizable & Easy to Install

Available in standard and customized dimensions, mesh sizes, and colors, our FRP gratings can be tailored to fit specific project needs. Lightweight yet sturdy, they are easy to transport, cut, and install right on site using basic tools. This flexibility streamlines construction and ongoing facility maintenance, delivering substantial cost and time savings for industrial environments.

Long-lasting & Low Maintenance Solution

With a service life of 15+ years under typical industrial conditions and virtually no rust or rot, FRP gratings require minimal upkeep. Their high strength-to-weight ratio and ISO 9001:2015-certified quality ensure lasting performance, reducing long-term replacement and repair costs. They retain full functionality in a wide range of temperatures from -40C to +120C.

FAQ's of Industrial FRP Grating:

Q: How is Industrial FRP Grating installed and can it be modified on site?

A: Industrial FRP Grating is designed for quick and easy installation. It is lightweight, so it can be lifted and positioned with minimal effort. The panels can be cut to specific dimensions or shapes on site using standard cutting tools, allowing for adaptable fitting to various areas. Fixing clamps or fasteners are commonly used to secure the grating to supporting structures.Q: What are the main benefits of using FRP Grating compared to steel or aluminum grating?

A: FRP grating offers superior corrosion and chemical resistance, making it ideal for harsh environments where metals might corrode or rust. It's non-conductive, offers excellent slip resistance, and is significantly lighter, simplifying handling and reducing structural load. It also requires very little maintenance, which lowers long-term operating costs.Q: Where can Industrial FRP Grating be effectively used?

A: Industrial FRP Grating is suitable for a wide array of applications, such as industrial flooring, walkways, drain covers, stair treads, and platforms. It is commonly used in factories, water treatment plants, chemical processing facilities, food processing areas, and outdoor platforms, thanks to its resistance to moisture, chemicals, and UV exposure.Q: What standards and certifications does your FRP Grating meet?

A: Our FRP Grating is manufactured to comply with major international standards, including ASTM, BS, EN, DIN, and IS, depending on regional requirements. It undergoes regular quality checks under ISO 9001:2015-certified QC systems, ensuring reliable performance and safety.Q: Is FRP Grating safe to use in outdoor or extreme temperature environments?

A: Yes, the grating is UV stabilized, providing excellent outdoor weather resistance without degradation. It remains structurally sound across a wide temperature range from -40C to +120C, and its fire retardancy (ASTM E84 Class 1) further ensures safe use in challenging industrial or climatic conditions.Q: How long does FRP Grating last under normal industrial conditions?

A: When installed in standard industrial environments, FRP grating typically delivers a service life exceeding 15 years. Its durability comes from high-quality fiberglass reinforcement and advanced resin systems designed to withstand physical, chemical, and UV-related stresses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pultrusion Section Category

FRP Grating

Price 1500 INR / Square Meter

Minimum Order Quantity : 1 Square Meter

Product Type : FRP Grating

General Use : Industrial Flooring Platforms Walkways

Shape : Rectangular

Dimension (L*W*H) : Customizable

Pp Electroplating Tank

Price 45000.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Pp Electroplating Tank

General Use : resist harsh acids and alkalis, ensuring safe, longterm use in electrochemical treatment plants, automotive workshops, hardware manufacturing units, and metal finishing industries.

Dimension (L*W*H) : as per required

Frp Hand Railing

Price 700 INR / Square Meter

Minimum Order Quantity : 1000 Square Meters

Product Type : FRP Hand Railing

General Use : Industrial safety and walkway protection

Shape : Linear/Balustrade

FRP Turnkey Air Pollution Control System

Price 100000 INR / Piece

Minimum Order Quantity : 1 Liter

Product Type : Turnkey Air Pollution Controller

General Use : Air Emission Treatment Removes toxic gases, fumes, and particulate matter before releasing air into the environment. 2. Chemical Processing Units Controls emissions of acid vapors, chlorine, ammonia, and other corrosive gases. 3. Pharmaceutical & Bulk Drug Plants Treats solvent vapors, fumes, and chemical exhausts to meet pollution control norms. 4. Metal Finishing & Electroplating Plants Captures acid mist, NOx, and other harmful byproducts from surface treatment processes. 5. Fertilizer & Pesticide Units Handles ammonia, sulfur compounds, and other odorous or hazardous emissions. 6. Dye & Pigment Industries Controls emissions from reactors, scrubbers, and blending tanks. 7. Foundries & Fabrication Plants Removes smoke, fine dust, and fumes generated during melting or welding.

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry